Maintenance

OTRONIX provides Hardware, software technical support and software upgrade service.

Also periodic maintenance and emergency system diagnotic activity can be served by contract.

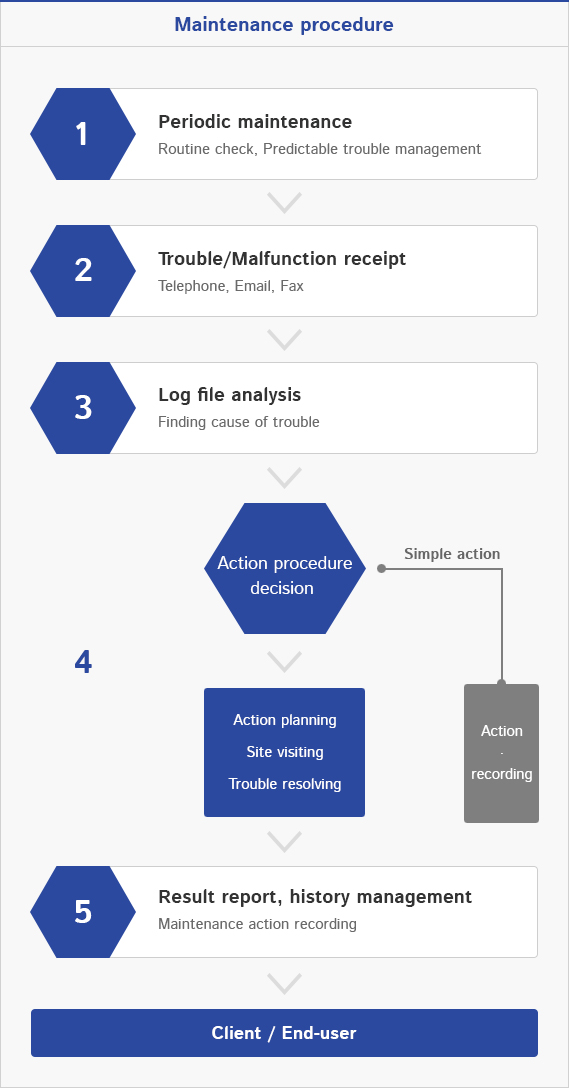

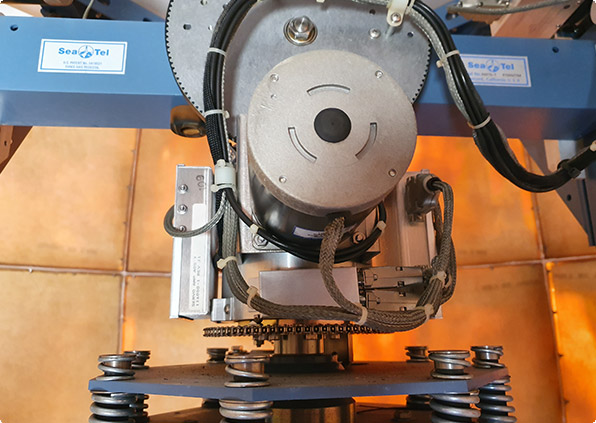

![]() Maintenance procedure and activity description

Maintenance procedure and activity description

Periodic maintenance, monthly regular system check service can be done to prevent system malfunction or trouble. And we are ready to respond to the Emergency call.

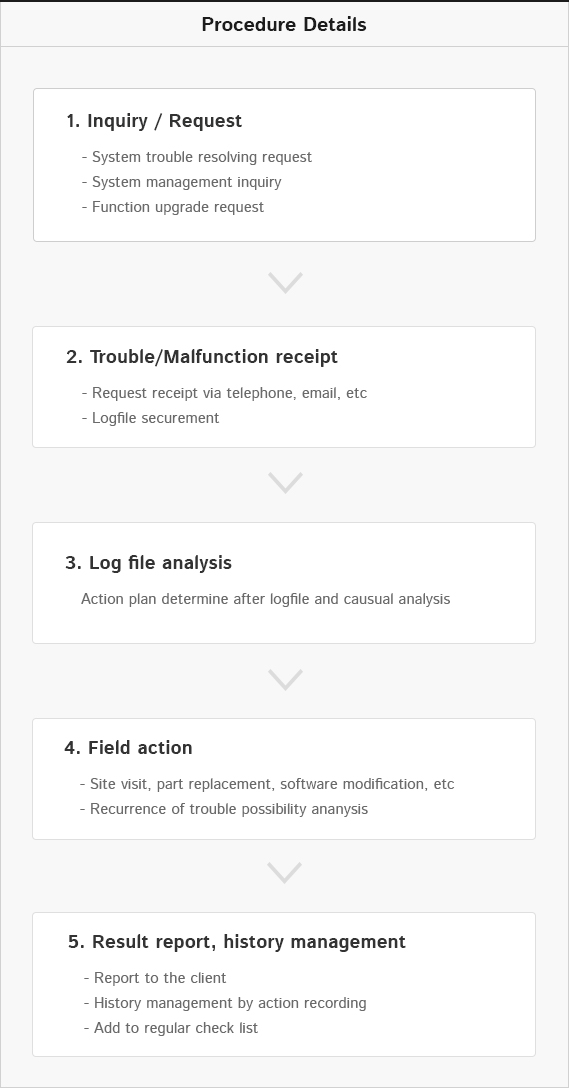

![]() Buoy systems

Buoy systems

OTRONIX serves buoy manufacturing, mooring, operation status monitoring and maintenance service. Maintenance can be done at site or Otronix buoy manufacturing facility, Donghae.

| Buoy system check list | |

|---|---|

| Sensor check & Calibration | Comparison sensor data with standard sensors and calibration can be done at the site. |

| Cable & connector check | Cable wearing, short, disconnection can be occur at moving buoys. |

| Bio-fouling removal | Buoys used to be operated as long term monitoring. Bio-fouling can be found any kind of buoy. |

| System status check | Buoy systems work in hot or cold, dry or humid environment with wave motions. Water leakage, corrosion should be avoided. |

Structure stability check

Structure parts check

Data logging system check

Cables and connectors check

Underwater sensor check

Diver check

Bio-fouling removal

Electronic devices check

Navigation light check

Power system check

Sensors check

Sensor check and solar panel cleaning

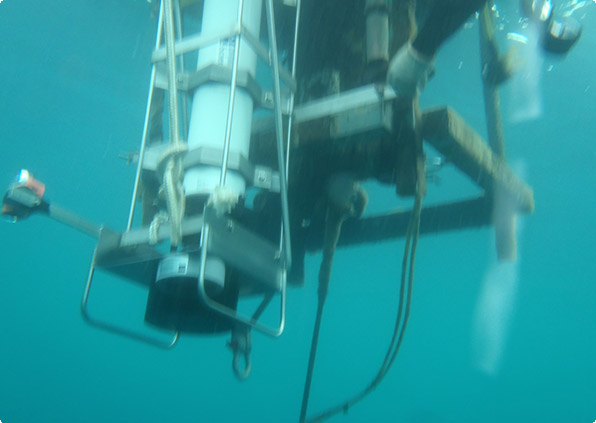

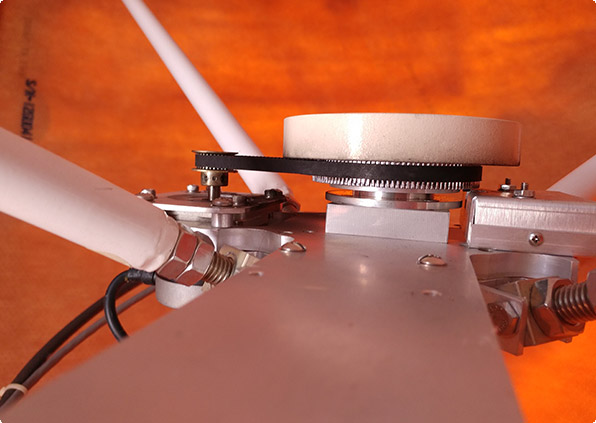

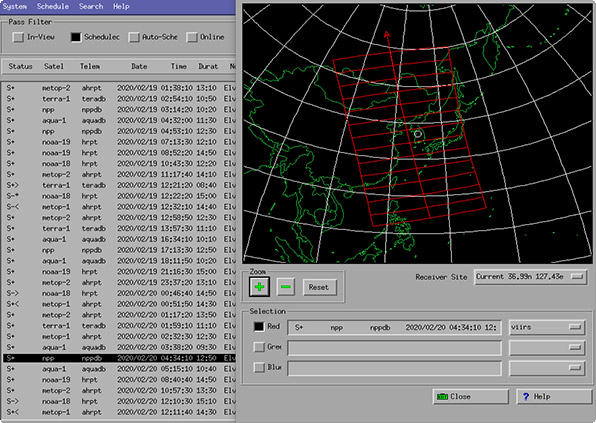

![]() Satellite receiving system

Satellite receiving system

Terascan system maintenance : OTRONIX cooperates with system manufacturer, SeaSpace Corp. We can provide maintenance service for stable system operation, trouble shooting, software update.

Periodic maintenance

– Monthly site visit and system check

| Check list | |

|---|---|

| Software | – Orbital elements update check – Orbit schedule update check – GPS status check – Receiver communication check – Antenna communication check – Data quality check |

| Hardware | – Antenna motion check – Server and auxiliary device check – Plug and connector check – Signal cable check |

| Emergency check | Otronix engineer can reach to the site in 4 hours around Seoul, Gyunggido, 6 hours for other places. We will resolve the malfunction a.s.a.p. |

Antenna motion check

RF device check

Receiver check

Acquisition and processing server check

Software operation check

Radome leakage check

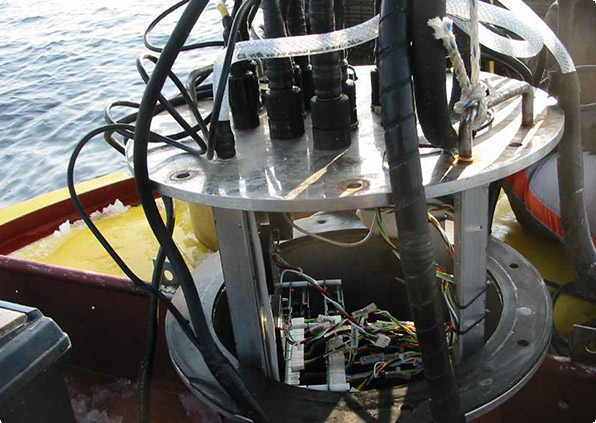

![]() Hydraulic Measurement System

Hydraulic Measurement System

HMS maintenance : HMS system installed on the river bridge has multiple sensors to measure low-water season flow and flood season flow. Low-water sensors are always stay in water, so periodic sensor cleaning is required.

| System check list | |

|---|---|

| Sensor check | Bog moss, floating matter removal. Transducer check, Mount tightness check |

| Cable check | Cable wearing and tightness check |

| Electronic device check | Corrosion, leakage check, Operation status check |

ADVM system check

Check electronic devices in enclosure

Cable check

Transducer check

Underwater device and cable check

UVM system check

Electronic devices check

Flood season sensor and cable check

Floating matter removal

Low level sensor check